Maintaining your vehicle's timing belt is one of the most crucial aspects of engine care. This vital component ensures proper synchronisation between the crankshaft and camshaft, allowing your engine to operate smoothly. Without proper maintenance, a failing timing belt can lead to catastrophic engine damage and costly repairs. This comprehensive guide will walk you through essential maintenance practices to keep your engine running at peak performance.

Understanding the Signs of Timing Belt Wear

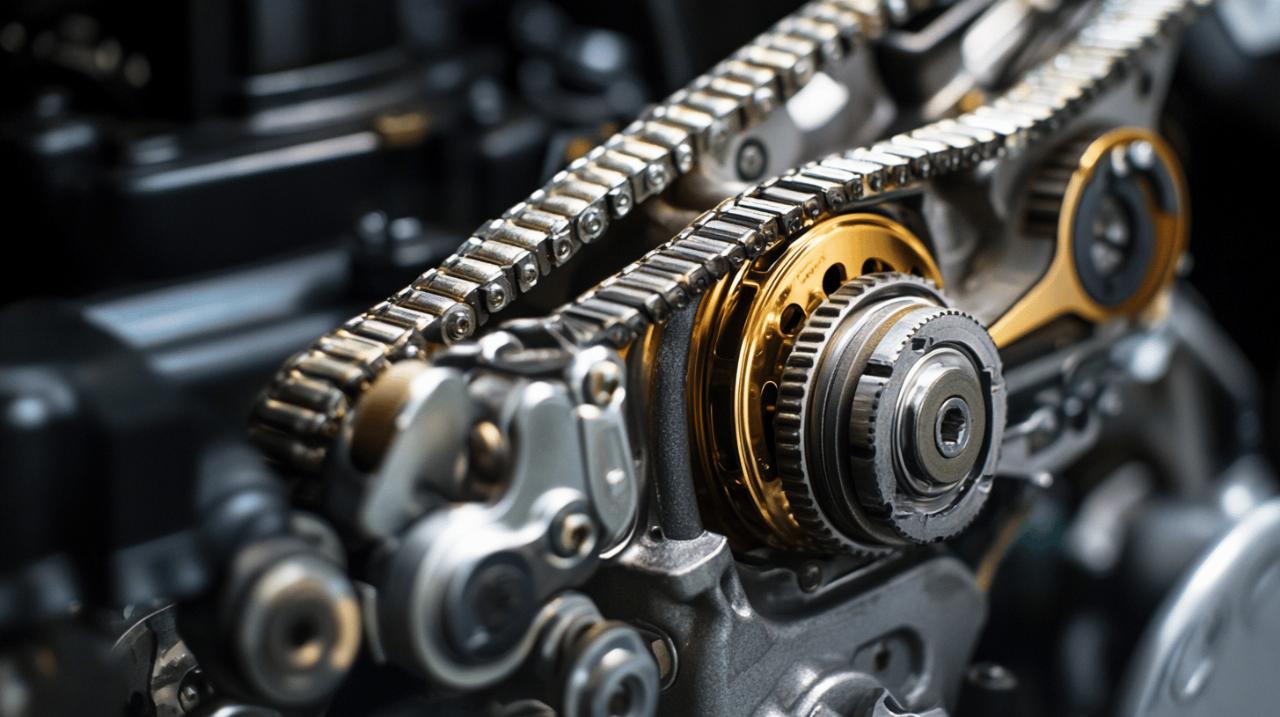

The timing belt is a reinforced rubber component that works tirelessly under extreme conditions. As Motor Publish experts have noted in their automotive guides, recognising early warning signs can save you from unexpected breakdowns and expensive engine repairs. Being proactive about timing belt maintenance is particularly important for European vehicles, which often have specific service requirements.

Visual indicators of deterioration

Examining your timing belt requires removing the protective plastic cover that shields it from debris. Once exposed, look for fraying along the edges, cracks across the belt surface, or glazing that indicates excessive heat exposure. These visual cues suggest that the reinforced rubber material is breaking down. Even if your vehicle has low mileage, remember that age-related factors can cause a 10-year-old timing belt with fewer than 50,000 miles to be just as prone to failure as one with 100,000 miles accumulated over five years.

Unusual noises and performance issues

Your engine will often communicate timing belt problems through distinctive sounds and performance changes. A ticking noise from the engine compartment, particularly during startup, can indicate belt deterioration. Other warning signs include engine misfires, rough idling, unexpected loss of power during acceleration, or in severe cases, complete failure to start. The engine may also run erratically as the synchronisation between the crankshaft and camshaft becomes compromised, affecting valve timing and overall engine performance.

Following manufacturer guidelines for replacement

Different vehicle manufacturers specify unique replacement intervals for timing belts based on extensive testing and engineering considerations. These guidelines are not arbitrary suggestions but calculated recommendations to prevent catastrophic failure.

Decoding service intervals in your vehicle manual

Your vehicle's owner manual contains specific timing belt replacement schedules that should be followed diligently. While the general replacement range spans from 50,000 to 100,000 miles or every 5 to 10 years, manufacturer specifications can vary significantly. For instance, Ford typically recommends replacement at 144,000 miles or 120 months, while Vauxhall suggests a more conservative interval of 60,000 miles or 6 years. These differences reflect variations in engine design, belt materials, and operating conditions that the manufacturer has accounted for during testing.

Mileage vs Age Considerations for Timing Belts

When determining when to replace your timing belt, consider both mileage and age rather than focusing on just one factor. Even if your vehicle hasn't reached the mileage threshold, rubber components naturally degrade over time due to heat cycling, environmental exposure, and chemical changes. This degradation occurs regardless of how frequently the vehicle is driven. A timing belt that has aged beyond the recommended timeframe presents a significant risk even if the vehicle has been used sparingly, making regular inspection essential for vehicles that don't accumulate high mileage.

Proper tension techniques for new timing belts

Installing a new timing belt requires precise tension adjustment to ensure optimal performance and longevity. Too tight, and the belt risks premature wear and increased strain on bearings; too loose, and it may skip teeth, causing engine timing issues or complete failure.

Using tension measurement tools correctly

Professional mechanics use specialised tension gauges to achieve the exact manufacturer-specified tension. These tools measure the force required to deflect the belt a certain distance, providing an accurate reading of tension. Digital tension meters offer the most precise measurements, while beam-style gauges provide reliable readings when used correctly. The proper technique involves positioning the gauge at the longest unsupported span of the belt, applying pressure at a 90-degree angle, and taking multiple readings to ensure consistency before making final adjustments to the tensioner mechanism.

Common mistakes when adjusting belt tension

One frequent error during timing belt installation is relying solely on feel rather than measurement tools. What might seem appropriately tight can actually be significantly over or under the required specification. Another mistake is failing to rotate the engine through several complete revolutions after installation to verify proper alignment of timing marks and to allow the belt to settle into position. Additionally, some mechanics neglect to recheck tension after this initial rotation, when minor adjustments are often necessary to compensate for the belt's initial stretching and seating.

Related components to inspect during replacement

A timing belt replacement presents the perfect opportunity to examine and potentially replace associated components that work in concert with the belt. This preventative approach can save considerable labour costs since these components are already accessible during the belt replacement procedure.

Water pump assessment and replacement

In many engines, the water pump is driven by the timing belt, making simultaneous replacement logical and cost-effective. Even if the water pump appears functional, replacing it preventatively during timing belt service eliminates the risk of failure shortly after, which would necessitate disassembling the same components again. When selecting replacement parts, comprehensive timing belt kits that include the water pump (often designated as KD kits) ensure component compatibility and uniform quality. Quality manufacturers provide silicon carbide seals in their water pumps that offer superior durability compared to standard ceramic seals.

Evaluating tensioner pulleys and idlers

The tensioner and idler pulleys guide and maintain proper tension on the timing belt throughout its operation. These components contain bearings that wear over time and can seize, causing belt failure even if the belt itself is in good condition. During replacement, check these pulleys for smooth rotation, unusual noise, or play in the bearings. Any resistance or roughness indicates bearing wear that will accelerate belt deterioration. High-quality timing belt kits include these components, ensuring that the entire timing system is refreshed during service and eliminating potential weak points in the system.

Consequences of timing belt failure

The ramifications of timing belt failure extend far beyond simple inconvenience, potentially resulting in extensive engine damage that may approach or exceed the value of the vehicle itself. Understanding these consequences reinforces the importance of proactive maintenance.

Understanding interference vs non-interference engines

Engine design plays a crucial role in determining the severity of damage when a timing belt fails. In interference engines, the pistons and valves occupy the same space at different times during the engine cycle, with the timing belt ensuring they never meet. If the belt breaks, these components collide, resulting in bent valves, damaged pistons, and potentially ruined cylinder heads. Non-interference engines have clearance between these components, so a belt failure typically results in the engine simply stopping without internal damage. Knowing which type of engine your vehicle has helps assess the risk level, with interference engines requiring particularly vigilant maintenance due to the catastrophic consequences of belt failure.

Preventative measures to avoid catastrophic damage

Beyond adhering to replacement intervals, several practices can help extend timing belt life and provide early warning of potential issues. Regular engine oil changes with manufacturer-recommended lubricants are particularly important for wet timing belts that operate in an oil bath environment. Monitoring for oil leaks near the timing cover can identify seal failures that might contaminate the belt. Additionally, paying attention to engine performance changes and addressing them promptly can catch timing-related issues before complete failure occurs. For ultimate peace of mind, some owners opt for replacement slightly before the manufacturer's recommended interval, viewing the additional cost as insurance against much more expensive repairs.